Case Study

Case Study

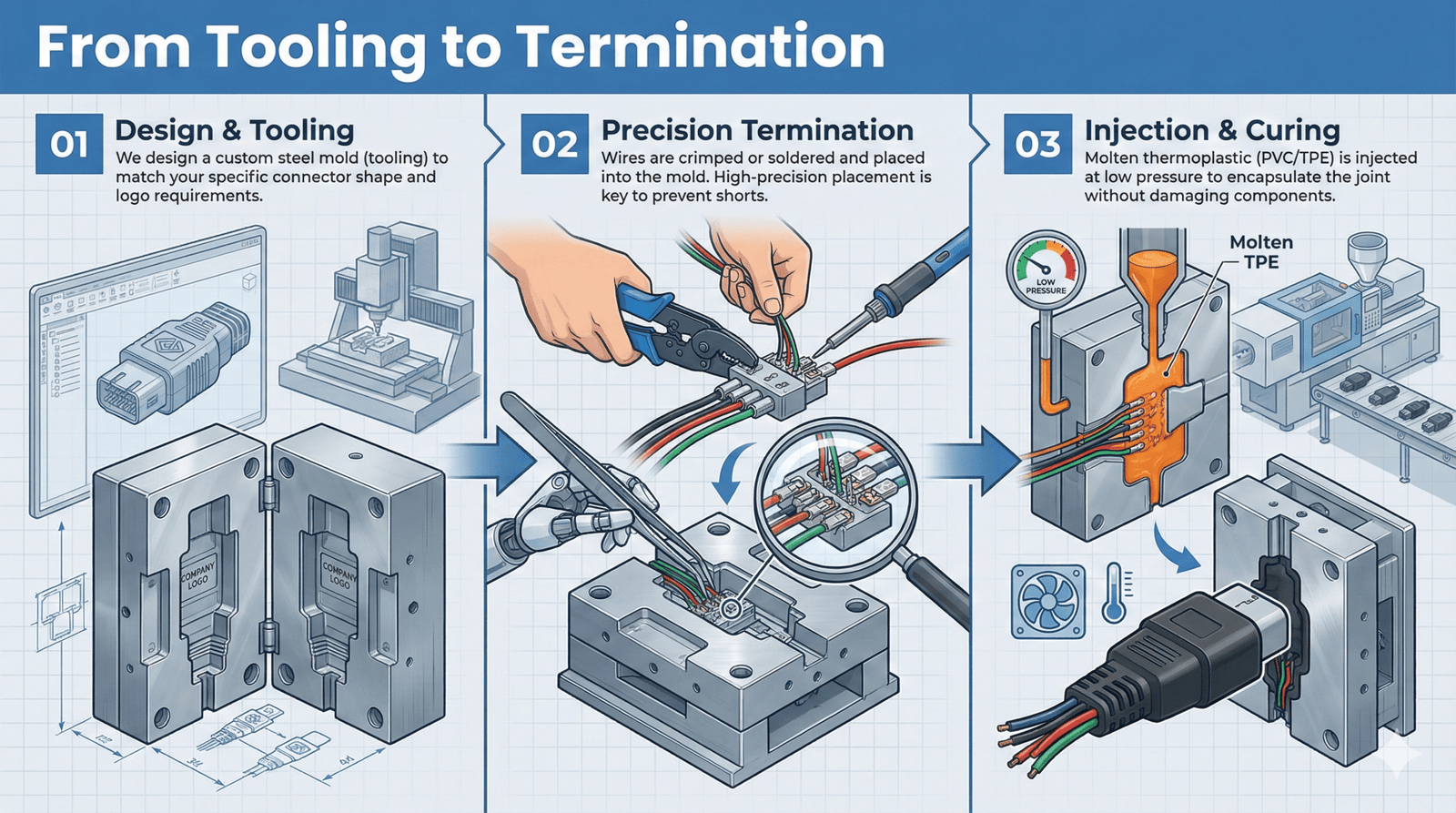

The 10-Million Cycle Challenge: Designing a High-Flex Cable for Robotic Arms?

"Every broken cable means hours of lost work and profits." A custom-engineered cable can eliminate...