Custom High-Voltage Charging Harness for EV Tier 1

How Cablum helped a global OEM achieve IP67 sealing and 360° EMI shielding under an aggressive 8-week SOP timeline.

Key Outcomes

The Challenge

A Tier 1 supplier of EV charging systems required a high-voltage harness that could withstand extreme temperatures (-40°C to 105°C) and provide superior EMI shielding to prevent interference with sensitive vehicle electronics.

The project was further complicated by an aggressive, time-sensitive product launch schedule and the absolute requirement for production under strict IATF 16949 standards.

Our Engineering Solution

Our engineering team collaborated directly with the client's design engineers to propose a comprehensive solution:

Material Selection

Selected specialized XLPE wires & TE Connectors for high-temp resistance and a TPU overmold for durability.

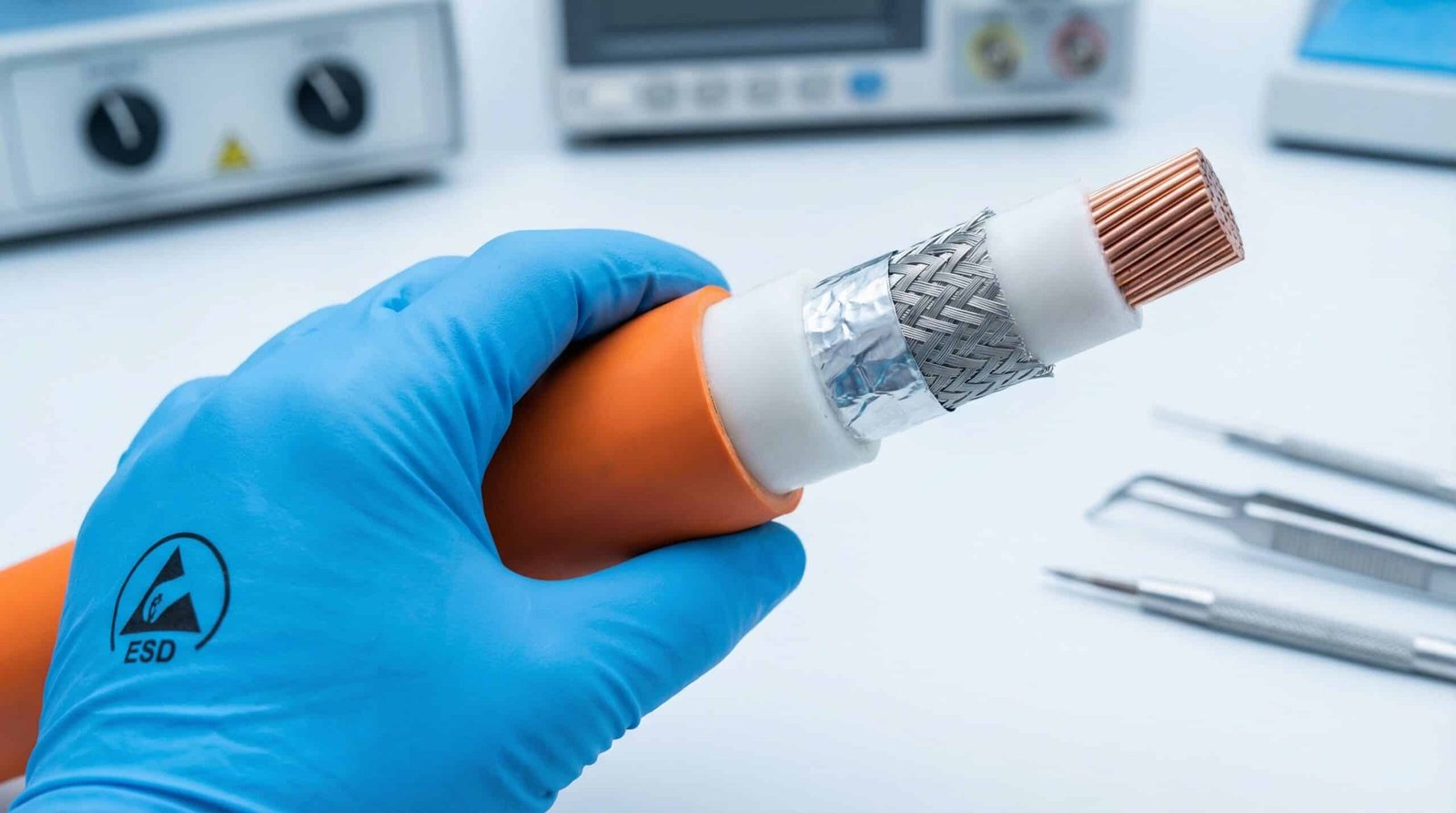

Double Shielding

Engineered a double-layered shielding design (Al-foil + tinned copper braid) to provide 360° EMI protection.

The Results

-

Zero Defects Validation:

Passed 3000-hour thermal shock & vibration testing with zero failures.

-

On-Time Launch:

Met the critical Start of Production (SOP) deadline despite tight timelines.

-

IATF Compliance:

Full PPAP Level 3 documentation provided and approved on the first submission.

Project Snapshot

- Industry: Automotive EV

- Application: HV Charging

- Voltage: 800V System

- Standard: IATF 16949